A cooling tower is a device used to reduce the temperature of hot water used in industrial processes or air conditioning systems. This device removes the heat of water through the process of evaporation and contact of hot water with air. In the cooling tower, hot water enters the system and after cooling it is returned to the system to be used again. Cooling towers are available in different types, including open-circuit and closed-circuit cooling towers, each of which has its own characteristics and applications.

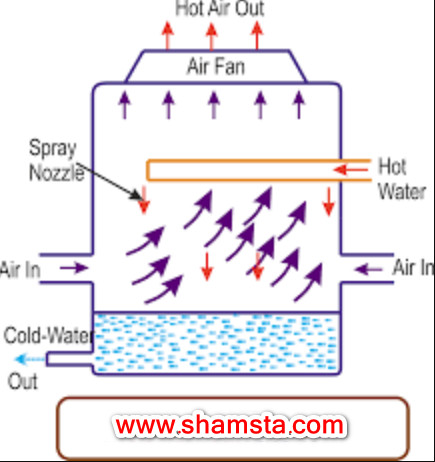

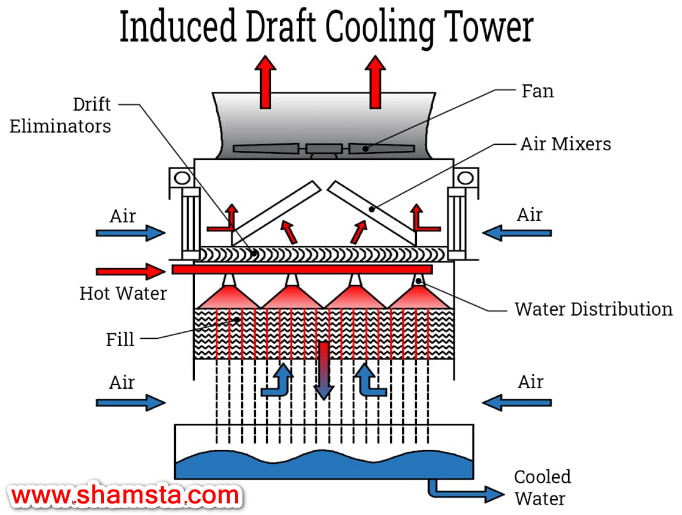

: Cooling towers work by using the evaporation process to cool hot water. Here is a summary of how a wet cooling tower works

Hot water enters the tower: hot water that needs to be cooled is pumped into it through pipes at the top of the tower.

Water distribution: hot water is turned into tiny droplets by the spray nozzles and is sprayed towards the bottom of the tower.

Contact with air: As the water drops fall down, they come into contact with the air entering the tower, which is drawn in by the fans.

Heat exchange: the heat of the water is transferred to the air and causes a part of the water to evaporate. This evaporation process takes heat from the water and cools it.

Collection of cooled water: The cooled water is collected in a basin at the bottom of the tower and then returned through pipes to the process that heated it in the first place.

Hot and humid air exit: Hot and humid air that contains water vapor leaves from the top of the tower.

In dry cooling towers, instead of spraying water into the air, hot water flows through tubes inside the tower and transfers its heat to the air around the tubes. The heated air is removed from the tower by fans.

Cooling towers have a wide variety of applications, they can be used wherever there is a need to remove excess heat from water. Some of the most common applications of cooling towers are:

Cooling towers are an essential part of many industries and help keep equipment and processes cool as well as save water.

Cooling towers are composed of various components, each of which performs a specific task in the water-cooling process. Below we describe some of the main components of the cooling tower:

Cooling towers can be classified based on various criteria such as performance, in terms of water circulation circuit (open circuit and closed circuit), in terms of flow direction, in terms of water and air flow direction, type of construction and material. We continue to examine the types of cooling towers in terms of performance.

Wet cooling towers are devices used to remove excess heat from water used in industrial and air conditioning systems. These towers reduce the heat of hot water by evaporating water and contacting it with air.

Types of wet cooling towers

Increasing the efficiency of air conditioning systems and industries: Cooling towers significantly reduce the temperature of the return water from heating systems, which increases the overall efficiency of the system.

Water Savings: Cooling towers allow the system to use available water more efficiently and reduce overall water consumption.

Reduction of operating costs: By improving the efficiency of ventilation systems and reducing the temperature of equipment, operating costs are reduced.

Improving the environment: using cooling towers can help reduce energy consumption and reduce greenhouse gas emissions.

High initial costs: Installation and operation of cooling towers usually have high initial costs, which can put a heavy financial burden on companies.

Need for ongoing maintenance: Cooling towers require regular maintenance to maintain optimal performance, which can be costly and time-consuming.

Health hazards: If not properly maintained, cooling towers can be a breeding ground for bacteria and fungi that may lead to health problems.

Energy consumption: Although cooling towers help reduce energy consumption, they are also energy consumers and can increase energy consumption.

Noise: Cooling towers can produce a lot of noise, which may be problematic in some environments.

Finally, the selection and use of cooling towers should be done according to the specific needs and conditions of each project in order to benefit from its advantages and minimize its disadvantages.

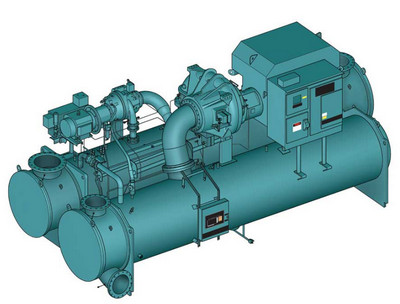

Cooling tower and chiller are both important equipment in air conditioning and industrial systems that are used to reduce temperature and control heat, but there are fundamental differences between them that we mention below and in terms of function and mechanism, application and We examine the advantages and disadvantages of each

Cooling towers are mainly used to cool water. The hot water from the systems enters the cooling tower, through the process of evaporation and contact with the air, its temperature decreases and then the cooled water returns to the system.

Chillers are devices that take heat from liquids (usually water) and transfer it to the outside environment through a refrigeration cycle. Chillers are divided into two types, compression chillers and absorption chillers.

: Difference between chiller and cooling tower in terms of application

Cooling towers are mostly used in power plants, refineries, petrochemical plants, and large air conditioning systems.

Chillers are used in air conditioning systems of buildings, hotels, hospitals, and shopping centers. They are also used in various industries for cooling equipment and processes.

: In terms of cooling type

Cooling in the cooling tower is based on water evaporation and heat exchange with air.

Cooling in chillers is based on the refrigeration cycle and the use of refrigerants (such as Freon).

Advantages of cooling tower over chiller: high energy efficiency in large scale and suitable for use in open systems with large water volume.

Advantages of chiller over cooling tower: It is suitable for precise temperature control of closed systems and water quality control

Disadvantages of the cooling tower compared to the chiller: it requires a lot of water consumption and the need for regular maintenance to prevent the growth of bacteria and deposits.

Disadvantages of the chiller compared to the cooling tower: high initial and maintenance cost and relatively high energy consumption.

Cooling towers and chillers both play an important role in heat and temperature management, but the choice between them depends on the type of application, project needs, and environmental conditions. Cooling towers are suitable for cooling large volumes of water in open systems, while chillers are more efficient for precise temperature control and closed systems.

Frequently Asked Questions

?What is a cooling tower and how does it work

A cooling tower is a device used to cool water in industrial and air conditioning systems. This device reduces the heat of hot water by evaporating water and contacting it with air.

? What are the types of cooling towers

Cooling towers are divided into two main categories: open circuit cooling towers and closed-circuit cooling towers. Each of these categories has further divisions based on the type of air flow (mechanical or natural) and the way of contact between air and water.

? What is the difference between an open circuit and a closed-circuit cooling tower

In an open circuit cooling tower, the hot water directly contacts the air and a part of it evaporates. In a closed-circuit cooling tower, water flows in a closed circuit and heat is transferred to the air through a heat exchanger.

?What are the advantages of using a cooling tower

Increasing the efficiency of air conditioning and industrial systems, saving water and energy, reducing operating costs and improving the environment are among the benefits of using cooling towers.

?What are the disadvantages and possible problems of cooling towers

High initial costs, the need for continuous maintenance, high water consumption and health risks caused by the growth of bacteria and fungi are some of the disadvantages of cooling towers.

? How to maintain the cooling tower

Regular maintenance includes periodic cleaning, inspection and replacement of worn parts, water level control and prevention of sedimentation and growth of bacteria are the basic measures to maintain the cooling tower.

? What is the water consumption in the cooling tower

Water consumption in cooling towers depends on the amount of heat required for disposal as well as environmental conditions such as temperature and humidity. By using water recycling systems, this consumption can be optimized.

? How to increase the efficiency of the cooling tower

Choosing the right cooling tower based on specific needs, regular maintenance, optimizing air and water flow, and using the right chemicals to prevent sedimentation and bacterial growth can help increase the efficiency of the cooling tower.

? Are cooling towers harmful to the environment

If properly maintained and managed, cooling towers can help reduce energy and water consumption and have less negative environmental effects. However, if not properly maintained, they can lead to health and environmental problems.

? What criteria should be considered in choosing a cooling tower

Required cooling capacity, type and quality of water, environmental conditions, installation and maintenance costs, and energy efficiency are among the criteria that should be considered in choosing a cooling tower.